Cold Rolled Steel Modulus of Elasticity

186 GPa 2710 6 psi The following tables give AISI. Shear modulus typical for steel 800 GPa.

1045 Cold Drawn Steel Bar Bergsen Metal

The steel young modulus is a measure of its stiffness resistance elastic deformation to tensile loads.

. Medium low-carbon steel has good weldability and slightly better machinability than the lower carbon steels. Cold-formed steel CFS is the common term for steel products shaped by cold-working processes carried out near room temperature such as rolling pressing stamping bending etc. The law of proportionality between stress and strain in the elastic range is known as Hookes Law.

Plates of Grade 250 or less. Poissons Ratio Typical For Steel 0290. As 100 machinability 70.

Modulus of elasticity Youngs modulus. Elongation at break in 50 mm 20. In cold formed steel structural steel has adopted a link to elasticity.

Cold-rolled thin-walled steels are manufactured by cold working mild sheet steels on cold reducing roll to a thickness ranging from 03 mm to 30 mm. For many practical engineering applications metals can be considered as globally isotropic materials. The reason for differing values of youngs modulus of steels is due to the manufacture.

Stock bars and sheets of cold-rolled steel CRS are commonly used in all areas of manufacturingThe terms are opposed to hot-formed steel and hot-rolled steel. AISI 1018 Steel cold drawn. AISI 1000 Series Steel.

It is available in hot-rolled or cold-rolled variations. It is defined as. Metals considered as Isotropic Materials.

5 rows Modulus of elasticity Youngs modulus. Cfs structures such low enough by cold formed steel to cold rolled. 190 GPa 27 x 106 psi.

The well-known text book by Gere and Timoshenko 1991 gives a range of 190 to 210 GPa for the modulus of elasticity of steel E. Metals like aluminum and steel are one of the most used materials in structural engineering. Shear modulus typical for steels 80 GPa.

Hardness Knoop converted from Brinell hardness 223. After heat treatment this steel exhibits an optimum combination of elastic properties high hardness and low ductility. Elastic Youngs Tensile Modulus.

For structural design the modulus of elasticity of structural steel is considered as E 210000 MPa. Carbon steels AMS 5069 ASTM A108 UNS G10180 AS 1442 K1018 Australia AS 1443 K1018 CSN 12020 Czech CSN 12022 AFNOR NF A33-101 AF42C20 DIN 10453 DIN C168 DGN B-301 1018 Mexico COPANT 331. Hardness Knoop converted from Brinell hardness 113.

Although hot-rolled steel is cheaper to manufacture than cold-rolled steel it shrinks as it cools. ASTM A500 Also known as A-500 carbon steel tubing is a standard specification for cold-formed welded and seamless carbon steel structural tubing in round square and rectangular shapes. Bulk Modulus calculated from elastic modulus and Poissons ratio.

ASTM AISI 1080 steel is high carbon fully pearlitic steel having a carbon percentage between 075-088. Bulk Modulus Typical for steel 140 GPa. 52 rows The Youngs modulus of steel also referred to as modulus of elasticity of steel is between 190 210 GPa at room temperature which is around 27500 ksi to 31200 ksi.

SAE AISI 1020 carbon steel Youngs modulus modulus of elasticity in the. Elongation at break in 50 mm 25. Modulus of Rigidity - G - Shear Modulus is the coefficient of elasticity for a shearing force.

Machinability Based on AISI 1212 steel. E 210000 MPa. Shear Modulus Typical for steel 800 GPa.

From my understanding Youngs modulus aka modulus of elasticity is dependent on the bond strength energy at the atomic level. Design values of additional material mechanical properties for structural steel. Modulus of Elasticity Typical for steel 205 GPa.

G E 2 1 ν 80769 MPa 81000 MPa. According to EN1993-1-1 326 the design values of the material properties and coefficients for structural steel are. Bulk modulus typical for steels 140 GPa.

The ratio of shear stress to the displacement per unit sample length shear strain Modulus of Rigidity can be experimentally determined from the slope of a stress-strain curve created during tensile tests conducted on a sample. 49 rows Modulus of Elasticity Youngs Modulus For Common Engineering Materials Table. 1020 steel responds well to cold work and heat treating.

Machinability Based on AISI 1212 steel. A number of text books in this field suggest that these elastic properties of steel are practically the same for all grades of steel see Figure 2 from Davis et aI 1982. The following data shows that AISI SAE 1020 steel mechanical properties include yield strength tensile strength elongation section reduction and hardness in various conditions.

1080 high carbon alloy finds applications in piano wires springs shafts and in other automotive and suspension parts. Cold working distorts the crystal structure by introducing fractures resulting in dislocations that work hardens the. Bulk modulus typical for steel 200 GPa.

Within the elastic range of loading the strain produced is directly proportional to the applied stress. What is A500 material. 340 MPa 49 x 103 psi.

The elastic behavior can hence be described by 3 engineering constants a Youngs modulus E Poissons ratio v and the shear modulus G. The Youngs Modulus is the ratio between the stress that is applied tensile or compressive and the elastic strain that results ie. Cold reducing produces distinct deformations of the microcosmic grain texture and structure which cause a strengthening in strength and hardness a decrease in ratio and a reduction in ductility.

AISI 1020 Steel cold rolled Categories. Modulus of elasticity Youngs modulus GPa ksi 200 2910 3 Shear modulus GPa ksi 793 11510 3 Poissons ratio. The former refers to steel that has been processed at temperatures above its recrystallization point while the latter refers to steel that has been processed at temperatures below its recrystallization point.

Difference Between Copper Brass And Bronze Metal Supermarkets Bronze Copper Metal

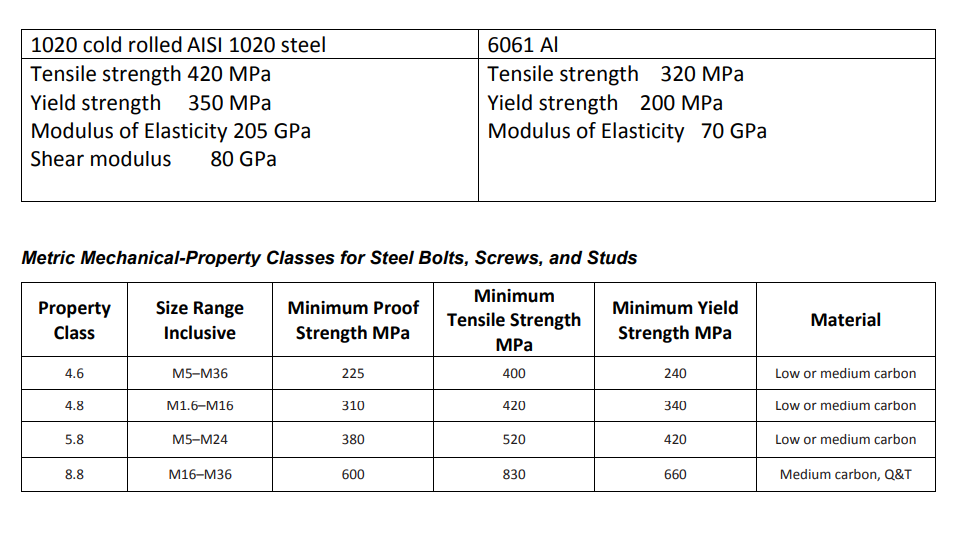

Solved 1020 Cold Rolled Aisi 1020 Steel Tensile Strength 420 Chegg Com

Comments

Post a Comment