List the Six Aspects of Lubrication Service

Utilizing lubrication the coefficient of friction which depends on area of contact and amount of load acting could be reduced and in turn heat and wear of the surfaces. A It reduces frictional forces between the moving components.

The Role Of Lubrication Management Professionals

Lubrication creates cooling effect on the engine parts.

. Pump with Reservoir stores and supplies the lubricant to the system. The key to success. It works while the machines engine is running along when all points are in.

17 terms 5 MATERIALS AND PROCESSES. The momentum of the rotating crankshaft splashes oil to other. Right storage handling the lubricant must be stored in the right conditions and handled correctly to avoid contamination and preserve its key characteristics.

In these types of the lubrication system it is commonly used in the two-stroke petrol engines such as scooters and motorcycles. Ad Request a Free Oil Testing Kit Today. Liquid oil Semi solid grease solid metals and solid chemicals The __________ separates moving surfaces which reduces the amount of.

Which of the following should not be done when changing an engines oil and filter. The heat generated by piston cylinder and bearings is removed by lubrication to a great extent. The primary objective of lubrication is to reduce wear and heat between contacting surfaces in relative motion.

Keeping fresh oil moving through the. The Key Elements of a Successful Lubrication Program. Mineral vegetable and synthetic.

When two or more metal parts rub on each other it creates friction in motion. A Torque the drain plug only enough to prevent leaking and loosening. Lets look at them one by one.

Lubricating oil must be clean. Types of Lubrication System. 27 terms 1 CHAPTER 2- RECIPROCATING ENGINE OPERATION.

As stated above there are three types of base oils used in a lubricant. It is said that lubricant is the lifeblood of our equipment. Instead mineral and synthetic base oils are often used in industrial applications.

Lubricant forms an oil film on the surface of metals converting solid friction into liquid friction to reduce friction which is the most common and essential function of lubricants. Automatic lubrication insures a continuous lubrication at a regular intervals the greasing points and the special points which have difficult access. Engine oil serves a vital purpose.

OTHER SETS BY THIS CREATOR. D Use an oil filter wrench to tighten the new oil filter. Following are the 6 main types of lubrication system.

Six steps for better lubrication management. Three types of lubricants. 10 terms 1 CHAPTER 1-RECIPROCATING ENGINES.

C It increases the life of machine and engine components. Due to the adhesion and strength of the film the lubricant penetrates the metal pores and clings to the surfaces of bearings and journals by keeping them wet when the journals are at rest and preventing metal to metal contact until the film of lubricant is built up. Understanding Lubricators and Lubricating Systems.

Submit a Sample for Free Lubricant Health Analysis. Right place for the oil or grease to reach the right surface it must be properly applied to the equipment. 5 Most Important Qualities of a Good Engine Lubricant.

Vegetable oils because of their lower oxidative stability and limited flow properties at cold temperatures are seldom used for industrial purposes. A general rule of thumb within the lubrication community is that over 60 percent of all mechanical failures are directly related to poor or improper lubrication practices 1. Lubrication can be linked to a POS system.

Following are the functions of lubrication. Ad Buy gas or diesel synthetic oils direct from the manufacturer. A proper quality lubricant is essential in engineering practice.

It reduces wear on engine components and ensures everything works efficiently at controlled temperatures. As a product application specialist I can identify three important aspects that manufacturers should consider when selecting a lubricant. Regardless of the manufacturer of system all automated lubrication systems have these 5 main components.

D Lubricants act as coolant. Lubrication forms an oil film between two moving surfaces. Reduced friction prevents heating and abrasion on the friction surface.

Good lubrication practice includes several key elements. Lubrication and cooling systems. Shop from a full line of lubricants for just about anything with an engine.

B It reduces the wear and tear of components. Controller Timer activates the system to distribute the lubricant. Lubricators and lubricating systems dispense or distribute oils and grease to mechanical devices such as bearings conveyor chains railroad rails air tools or packing glands for the purpose of minimizing friction between moving parts.

Lubricants lessen both rolling and sliding friction minimize wear and corrosion. Although the two can be featured together in an engine. C Wipe clean engine oil on the new filter O- ring seal.

It is the simplest form of the. The cost of the lubrication the cost of equipment maintenance and the cost of operational loss resulting from unscheduled downtime. Up to 8 cash back How the Engine Lubrication System Works.

B Use an oil filter wrench to remove the old filter. The oil circulates within the engine through splash lubrication or pressurize lubrication pump system which is the most preferable choice by manufacturers. It lubricates cleans and cools the many moving parts in an engine as they cycle thousands of times every minute.

Lubrication is required to reduce the frictional losses between metal to metal rubbing or sliding parts. Lubrication also reduces noise produced by the movement of two metal surfaces over each other. The splash lubrication happens when the crankshaft is partly immersed in an oil sump.

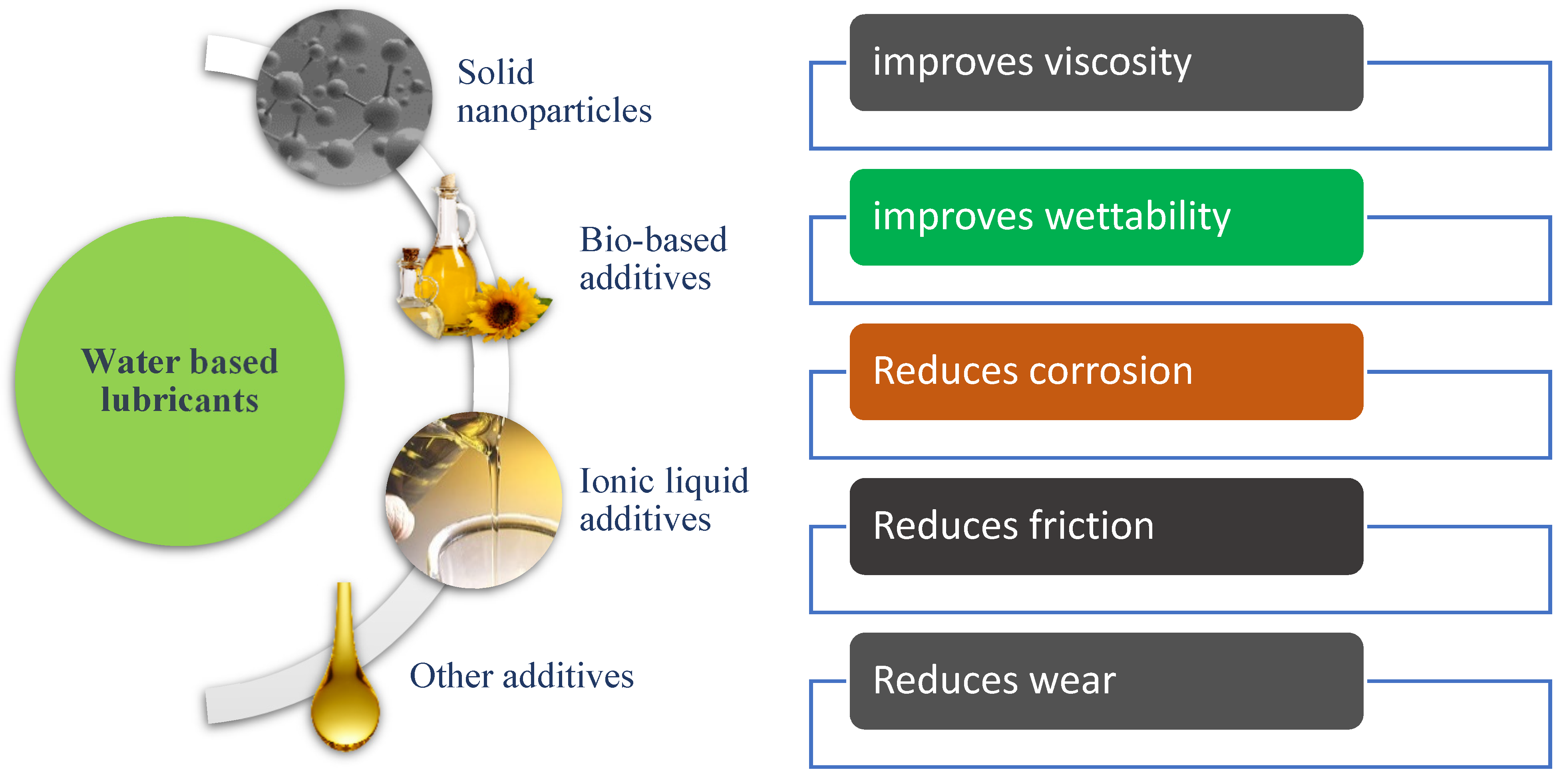

Lubricants Free Full Text Water Based Lubricants Development Properties And Performances Html

Mechanical Engineering Lubrication Chemical Structure Lubricants Physical Properties

Comments

Post a Comment